Repair details

Our repair service

Do you have a pump, submersible motor or fitting that needs to be repaired?

Just get in touch with us. We will then clarify the necessary steps together.

Regardless of whether it is a DKM&KKB product or a third-party product.

Third-party products such as centrifugal pumps like boiler feed water pumps from the manufacturers

HALBERG, KSB, FLOWSERVE, SULZER and many more,

Submersible motor pumps from the manufacturers

PLEUGER, KSB, RITZ, ANDRITZ, WILO, etc. and

Pumps and submersible motors up to a weight of 8 tonnes.

Or also ball valves from the manufacturers

KROMBACH, FLOWSERVE, ARGUS, PFANNENSCHMIDT, MAYER and many more,

up to a nominal diameter of DN800.

What sets us apart

- Quality and reliability

- Years of manufacturer expertise

- One point of contact for all products - pumps, valves and submersible motors

- fast response and delivery times

- customised services

- transparent communication

- worldwide on-site service

Procedure of our repair process

Collection by DKM&KKB or direct dispatch to us

In principle, you have the option of sending the products directly to our company headquarters:

DKM&KKB GmbH

Greenwichstraße 2

D-66482 Zweibrücken

Alternatively, simply send us the colli data (weight and dimensions of the pallet). We will then organise the collection for you.

Please send us the completed decontamination certificate.

Receiving inspection, dismantling, cleaning and diagnosis

We check different parameters depending on the product.

For pumps, we determine all clearances such as bearing clearances, throttle bushings, etc.

For motors, we measure the insulation value and record the axial and radial clearances.

The cleaning process of the products is carried out internally and externally. If necessary, parts are blasted with glass beads so that they are completely free of dirt, corrosion and other residues.

Depending on the medium, we use a certified chemical workplace to collect and dispose of any hazardous substances.

Cost estimate with findings report

In addition to a detailed report on the findings, we will send you a cost estimate for the repair.

This includes documentation on the condition of the products with damage patterns.

As well as an overview of the necessary reworking and spare parts required

After approval by our customers, the repair is carried out

You now decide whether and what we should repair on your product. Our colleague will contact you and make a note of all your questions and requests so that they can be passed on internally to the right people.

Construction

For third-party products, it may be necessary to measure worn components in order to manufacture new ones.

We measure hydraulic contours such as in impellers and guide wheels using 3D measuring systems.

We carry out reverse engineering in CAD and thus obtain the flow-guiding contour. We can then also produce casting models.

Mechanische Bearbeitung und Beschaffung notwendiger Ersatzteile

We use our machinery to manufacture replacement and repair parts for reconditioning and carry out necessary reworking, e.g. on housing parts.

We also rework fitting and sealing surfaces.

We are able to machine parts with unit weights of up to 1.5 tonnes and a diameter of 800 mm by turning/milling.

We can also machine pump and motor shafts up to 3 metres directly in-house.

We offer all standard machining processes - whether turning, milling, grinding, polishing or lapping.

Assembly & testing and acceptance

Pumps / motors and ball valves are assembled and tested.

The pumps and motors can be run on our in-house pump test bench. Acceptance is carried out in accordance with DIN EN ISO 9906

The ball valves are subjected to a strength and leak test in accordance with DIN EN 12266.

Functional testing of the valve actuators

In general, customised tests are also possible on request.

Documentation

Upon delivery, our customers receive the documents created for their own documentation.

Example of submersible motor pump repair

Two-stage submersible pump with 4-pole motor.

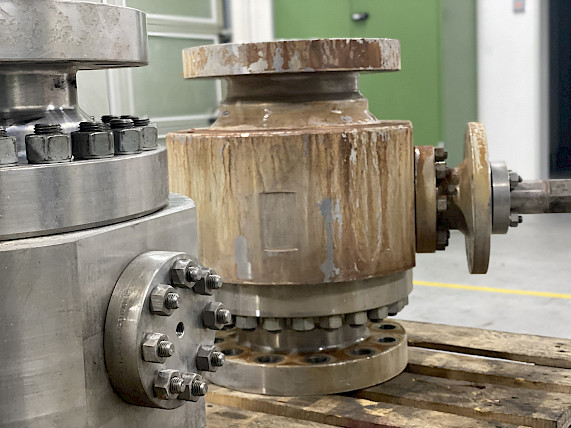

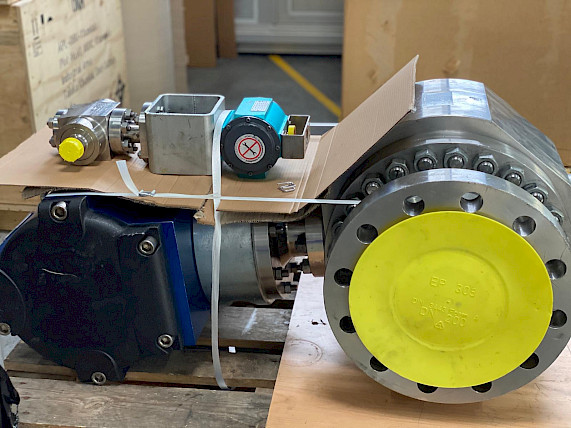

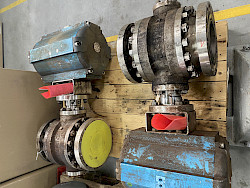

Example ball valve

High-pressure flanged ball valve DN200 PN160 and filling and bottom outlet ball valves DN300 PN40