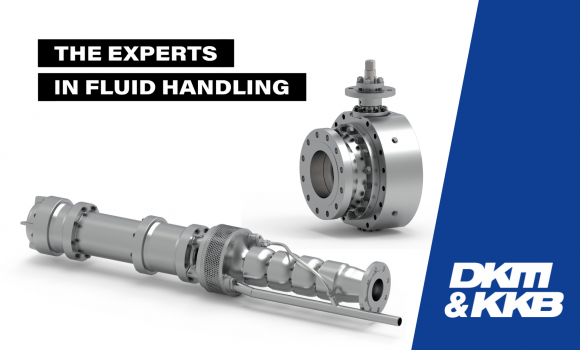

Products

High-performance valves, pumps and motors - Made in Germany

Is a product in your system not fulfilling expectations and needs to be adapted or replaced? Do you need a strong partner who knows the complex challenges of your industry?

We will work with you to find a suitable solution and manufacture high-quality, efficient fittings, ball valves, valves, pumps and motors for you. These are then tailored precisely to your requirements and framework conditions and come with a strong price-performance ratio and 24/7 support.

Fittings

Thanks to our constant innovation in research and development for your individual requirement profiles, we can offer you a wide range of valves - including the engineered ball valve, which we design according to your specifications.

Pumps

We offer a wide range of materials and applications for pumps. We attach great importance to energy efficiency and effectiveness and also customise our standard pumps to your individual requirements and conditions.

Motors

Whether submersible, tank or mine motors, with low, medium or high pressure: our motor series are also available in different versions and can therefore be optimised for your project.

Engineered products

As individual as our customers are, so are their processes. To meet their requirements, we customise our ball valves, pumps and motors accordingly. We cannot always fall back on a standard solution.

In such cases, we at DKM&KKB utilise the engineered-to-order process (ETO). In addition to clarifying all technical requirements, we design our products and their materials and construct the products. We are able to do this thanks to our in-house design programmes for valves, pumps and motors.

On request, we can also create a customised construction test sequence plan and define and specify quality test steps during production together with our customers. Production and acceptance are then carried out on our own test benches.

Delivery options

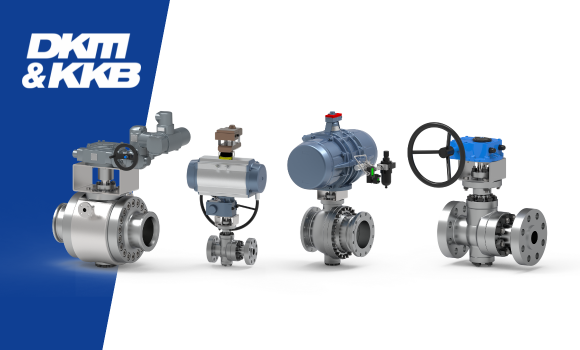

Delivery options for ball valves

Our ball valves can be supplied as a complete unit with drive (worm gear, electric, hydraulic or pneumatic actuators) and all accessories (e.g. control units). If required, we can also realise fast closing times for the ball valves.

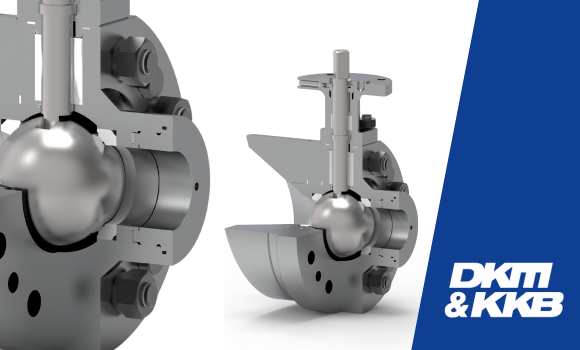

Constructive designs

All ball valves are available with a heating or cooling jacket and the corresponding connection flanges or sleeves.

If it is necessary to reduce the dead spaces in the ball valve, ball shells, also known as dead space shells, can be installed. These are available in different material variants.

Our ball sealing systems, whether soft or metal-to-metal sealing, have a spring-loaded design. This ensures that the sealing rings are optimally pressed against the shift ball in the event of wear. The resulting torque fluctuations are also equalised in the event of temperature fluctuations.

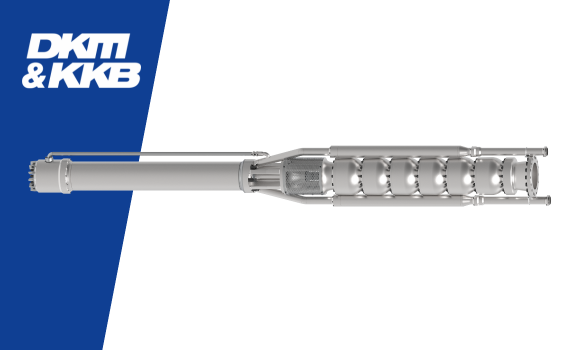

Delivery options for the pump units

DKM&KKB pump units manufactured to customer specifications are available as single or multi-stage centrifugal pumps. Typically, these are coupled with a water-filled motor as a standard motor or as a motor for special applications in particular fields of application.

In submersible pumps, the motor is mounted below the pump and the suction area of the pump is located above the motor. The power supply cable is located in a water-filled protective tube or is connected to the motor in a special protective cable.

The pumps are approved for operation in potentially explosive atmospheres.

Accessories for submersible pumps

Depending on requirements, we supply the complete range of technical accessories from riser pipes for the pumps, cable conduits for the motor, well heads and supply systems for mechanical seals. These accessories are customised and adapted to the various installation situations of our customers.

What can we do for you?

Do you have a question about our products or services? Or are you interested in working with us?

Tell us about your request and we will find a suitable solution together!